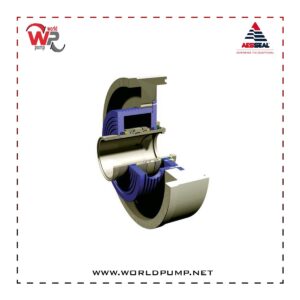

HDSS and HDDSS

The HDSS and HDDSS heavy duty slurry seals designed by aesseal for the arduous environment of the mining industry. Likewise، The robust seals built to withstand levels of pump vibration with large internal clearances accommodating levels of movement.

HDSS – heavy duty slurry seal range

AESSEAL® has been sealing slurries successfully for decades

throughout many industries, including:-

Mining

Minerals Processing

Water and Waste Water

Pulp and Paper

Sugar Refining

Power Generation

Chemical Processing

Flue Gas Desulphurisation

Liquids carrying abrasive particles represent the most common type of slurry applications found in industry. Also The percentage of solids, concentration and particle size create a combination which will result in abrasion and seal failure, if the correct seal and seal environment is not properly selected.Also The AESSEAL® HDSS Slurry Seal range of single and double mechanical seals have been designed to excel in these harsh abrasive slurries. Also Our wide range of seal support systems and bearing protectors compliment the HDSS™ range, allowing our technical experts to offer total packaged solutions for all slurry applications.

Over the years, AESSEAL® have sealed almost all major slurry pump types and models. Also Solutions for some of the more commonly encountered slurry pump manufacturers include; Warman®, Denver Orion®, Goulds® and KSB® to name but a few. for instance, the detailed table to the right, shows products available for the full range of Warman® AH pumps.

Also ALL applications, where our standard products do not directly fit. AESSEAL® will configure and adapt our components to ensure our products install directly into the equipment WITHOUT REQUIRING PUMP MODIFICATIONS. As well as a comprehensive range of products for slurry pumps, AESSEAL® also offer solutions for other types of slurry equipment such as slurry seals for Cellier and Stelzer mixers.

Download catalog for more information: Download cataloge