- Info@worldpump.net

- Location

Operating range

Shaft diameter: d1 = 1.000″ … 3.750″

Other sizes on request

Temperature: t= -40 °C … 220 °C (-40 °F … 428 °F) (Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination Q1Q1 or U2Q1

Pressure: p1 = 12 bar (174 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Axial movement: ±1.0 mm, d1 ≥75 mm ±1.5 mm

Materials

Seal face: Silicon carbide (Q1), Carbon

graphite resin impregnated (B), Tungsten

carbide (U2)

Seat: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E),

FFKM (K), Perflourocarbon rubber/PTFE

(U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G)

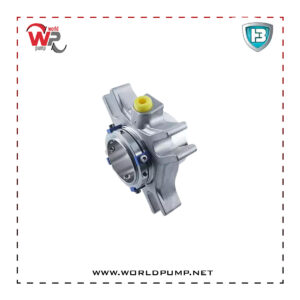

Features

Single seal

Available for standard (Cartex-ASPN) and big

bore (Cartex-ABPN) seal chambers

Cartridge

Balanced

Independent of direction of rotation

Single seals with flush (-ASPN, -ABPN) and with

quench combined with lip seal (-ASQN, -ABQN)

or throttle ring (-ASTN,-ABTN)

Advantages

Ideal for use in ANSI process pumps

Universal applicable for packings conversions,

retrofits or original equipment

Seal for standardizations

No dimensional modification of the seal chamber

necessary, small radial installation height

No damage of the shaft by dynamically loaded ORing

Extended service life

Installation faults are avoided, costeffective

No damage caused by dirt entered during

assembly

Straightforward and easy installation due to preassembled unit (reduced downtimes)