-

Chemical industry (aggressive / also other liquids)

-

Petrochemical industry (aggressive / other liquids)

-

Process engineering

-

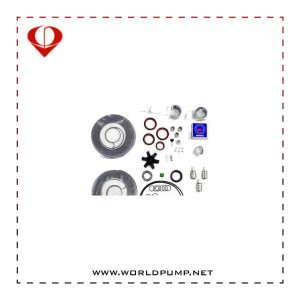

Pump Refinery

-

Biodiesel, also bioethanol applications

-

Renewable energy

-

Fossil-fuelled power stations

-

Seawater desalination/also reverse osmosis

-

Paper industry / also pulp industry

-

General industry

-

Steel industry

-

Alcohol industry

-

Food industry / also beverage industry

-

Also Sugar industry

MegaCPK Benefits

-

Hydraulic characteristics optimised for excellent efficiency and also NPSH, ensuring energy-efficient and environmentally friendly use of resources

-

Lower investment costs as duty points required can be achieved with smaller pump sizes

-

Lower operating costs due to reduced energy consumption, optimised spare parts concept and also hard-wearing, service-friendly design

-

Flexible use due to modular design regarding hydraulic system materials, sealing elements, bearing brackets, coupling, baseplate and drive

Technical Data

Function:Pump

Connection type:Flange

Drive concept:With electric actuator

Pump Max. flow rate:1160 m³/h

Min. flow rate:2 m³/h

Max. head:162 m

Pump Min. head:2 m

Mains frequency:50 Hz,60 Hz

Pump Mains voltage:400 V,460 V

Casing material:EN-GJL-250/A48 CL 35B,GP240GH+N/A216 GRADE WCB,G17CRMOV5-10,GX5CRNIMO19-11-2/A743 GRADE CF-8M,

GX3CRNIMOCUN24-6-2-3/GX2CRNIMOCUN25-6-3-3/A9951B

Nominal pressure:PN 25

Pump Max. allowed working pressure:25 bar

Suction behaviour:Non-self-priming

Max. allowed fluid temperature:400 °C

Pump Min. allowed fluid temperature:-40 °C