Operating principle

The high speed and adjusted tolerances between the rotor and the stator result in high suction potential, the product is suctioned from the bottom of the tank and driven to the center of the head.

The product is suctioned from the lower part of the head and the rotor thrusts it radially.

Passing through the openings of the stator the product is mechanically sheared. the particles are sheared by the rotor at 20 m/s. And finally the product is hydraulically sheared while leaving the stator through the slots at a high speed . At the same time the product returns to the working head ensuring the mixing circle and generating a strong circulation inside the tank. The combination of the vertical suction and radial thrust results in a circulation flow.

If the size and the power of the mixer are correctly selected, the ingredients contained in the tank pass through the working head hundreds of times that promotes a progressive and uniform homogenization.

Other important feature is the possibility to minimize the aeration of the product.

Design and features

High shear, particle size reduction to less than 100 microns.

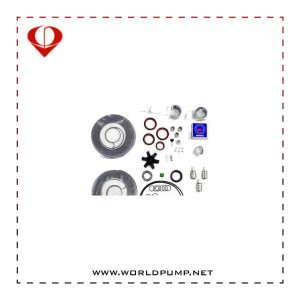

V-ring.

Slotted head (standard).

Possibility to replace the stator and the bushing without disassembling the mixer.

Various types of interchangeable heads.

Motors: IEC B5, IP55, F-class insulation.

Materials

Parts in contact with the product: AISI316L

Guide bushing: PTFE

V-ring: NBR

Options

DIN2632-PN10 flange or rectangular flange for the assembly on a tank.

Circulation propeller.

Downthrust propeller.

Peak friction bushing and ceramic lined shaft for abrasive media.

Disintegrating head.

Fine screen head.

Intermediate flange for long mixers.

SLIM system.

Upper suction head.

Motor shroud.

Other motor protections.