LabTecta 66KSB

Verification tested contacting and non-contacting bearing seal designs with pump bearing chamber bearing plates. Also Proven to increase equipment reliability in KSB CPK pumps. Also Designs which conform to IEEE Std. 841-2009 for electric motor bearing protection. Corrosion resistant stainless steel bearing plate construction ensures no coating is required.

Features:

Inventoried motor and also pump bearing chamber plates

Fits KSB CPK process pumps: P02, P03, P04 and P05

For use with AESSEAL API610 compliant bearing seals

Patented ‘O’ ring design provides superior and also more reliable sealing

Bearing Protection

The most cost effective reliability upgrade for your equipment

The LabTecta 66 range can eliminate the cause of 52% of your bearing failures.

Through its dynamic lift technology, it allows the equipment to breathe when

running, but is perfectly sealed when the equipment isn’t running,

preventing the ingress of contaminants.

Application specific designs(LabTecta 66KSB)

LabTecta 66 can be used to upgrade applications that are used in difficult locations, or are prone to premature bearing failure.

Steam turbines (LabTecta 66ST)

Axial movement (LabTecta 66AX)

Oil flooded applications (LabTecta 66FS)

Split-seal designs for easier installation (LabTecta 66RDS)

Pillow blocks (LabTecta 66PB)

Inboard / outboard air purge for difficult environments (LabTecta 66IAP / LabTecta 66OAP).

Reducing Bearing Failure

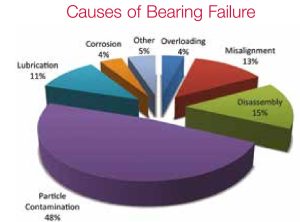

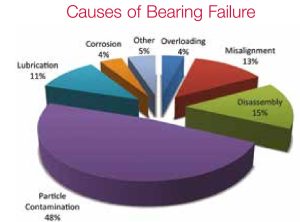

52% of Bearing failures are due to contamination of the bearing oil*.

This represents 20.8% of all rotating equipment failures

A major study into equipment reliability has shown 48% of all bearing failures are due to particle contamination of the bearing oil, with an additional 4% due to corrosion caused by contamination of the bearing oil.

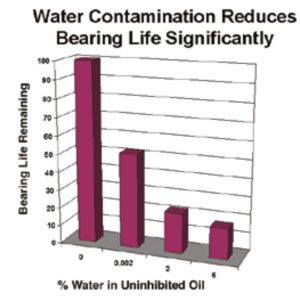

Reducing Water Contamination

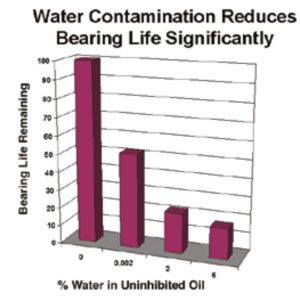

Research conducted by a major academic institution has shown that water contamination as low as 0.002% (20ppm) in some oils can reduce bearing life by as much as 48% LabTecta 66 reduces bearing failure by:

Preventing water ingress

Also Preventing dust ingress

Eliminating shaft damage due to rubbing

Download catalog for more information: Download cataloge