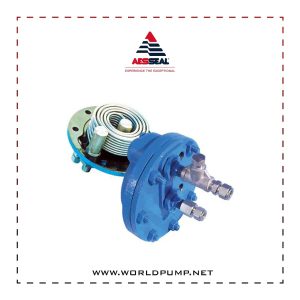

The CKDA glandless cartridge dual seal designe for AhlstarUP pumps. The seal uses a multi-spring design that ensures the seal faces evenly lead and therefore improve seal life. The cartridge design makes installation simple and also the seal can retrofitt to existing pumps without modification. The seal includes an unique flow inducer(patent pending) that helps improve barrier/buffer fluid flow to remove heat from the seal and optimise the seal face cooling.Also The dual seal hydraulically balance ensuring that it performs well at high and low barrier to process pressure differentials.

Features

- Multi-spring energized

- Cartridge design

- Patent pending flow inducer

- Bi-directional flow inducer

- Hydraulically balanced faces

CKSA & CKDA

The CKSA and CKDA seals designe to fit the full six bearing frame range of the AhlstarUP pump models.

AESSEAL® is believed to be the only seal manufacturer to offer a fully integrated and also glandless cartridge mechanical seal range for these pumps, which were launched by Sulzer in 2006 with a view to superseding the APP and APT ranges. The AESSEAL® design features and also benefits show below:

Cartridge design — an absolute must for reliable field seal replacement

Easy to retrofit — no modification to the equipment needed

Bi-directional flow induction — effective barrier heat removal (dual seal only)

Independent multi-spring faces — a more reliable solution for longer life

Axial sealing between impeller hub and also seal sleeve — prevents rotary face hang up and failure

Monolithic rotary faces — resilient mount reduces effect of impeller torque

To increase seal reliability and also save significant volumes of cooling water it is recommended that all double seals use in conjunction with the AESSEAL® water management systems can save up to 4.2 million litres / 1.1 million gal (US) of water per annum per seal (based on 8 l/min / 2.1 US gpm).

See next page for further information on system products.